Building the Future of Factory Maintenance:

How AX Smart Assistant Transforms Expert Knowledge into Action

In high-tech manufacturing, deep domain expertise is essential but understanding how each industry operates and transferring that knowledge to newcomers is equally critical. Although valuable insights exist across maintenance logs, engineering reports, SOPs, training materials, alarm codes, and defect analyses, this information is often scattered and siloed. As a result, it becomes difficult to access at the exact moment it’s needed, whether an engineer is troubleshooting equipment, inspecting a device, or training the next generation of operators.

That’s where Alpha X’s Smart Assistant comes in.

From Documents to an Industrial Brain

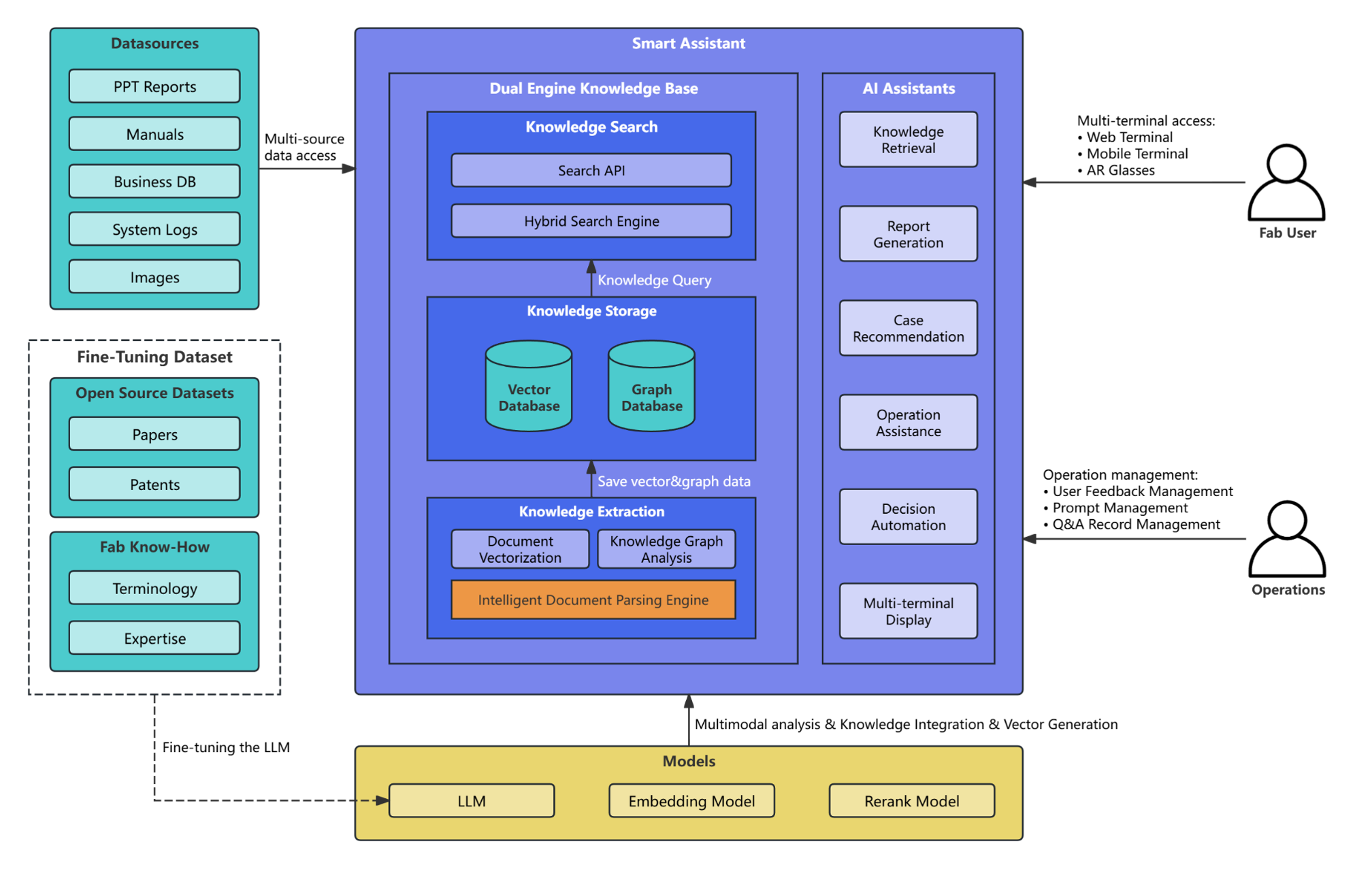

At the heart of Smart Assistant is a powerful enterprise-grade knowledge base. This isn't just a file storage system, it's a highly organized, intelligent repository built from all the internal documents a factory produces: PowerPoints, PDFs, Word documents, training guides, equipment manuals, past failure analysis, and more. Smart Assistant parses, standardizes, and organizes all this content.

This foundational knowledge engine supports two core capabilities:

1. Question & answer (Q&A) — Engineers can ask natural-language questions (“How do I handle alarm code X123?”) and instantly get clear guidance.

2. Expertise Transfer — As the system accumulates institutional know-how, it preserves and shares expert-level insights even with new or junior staff, reducing reliance on individual human experts.

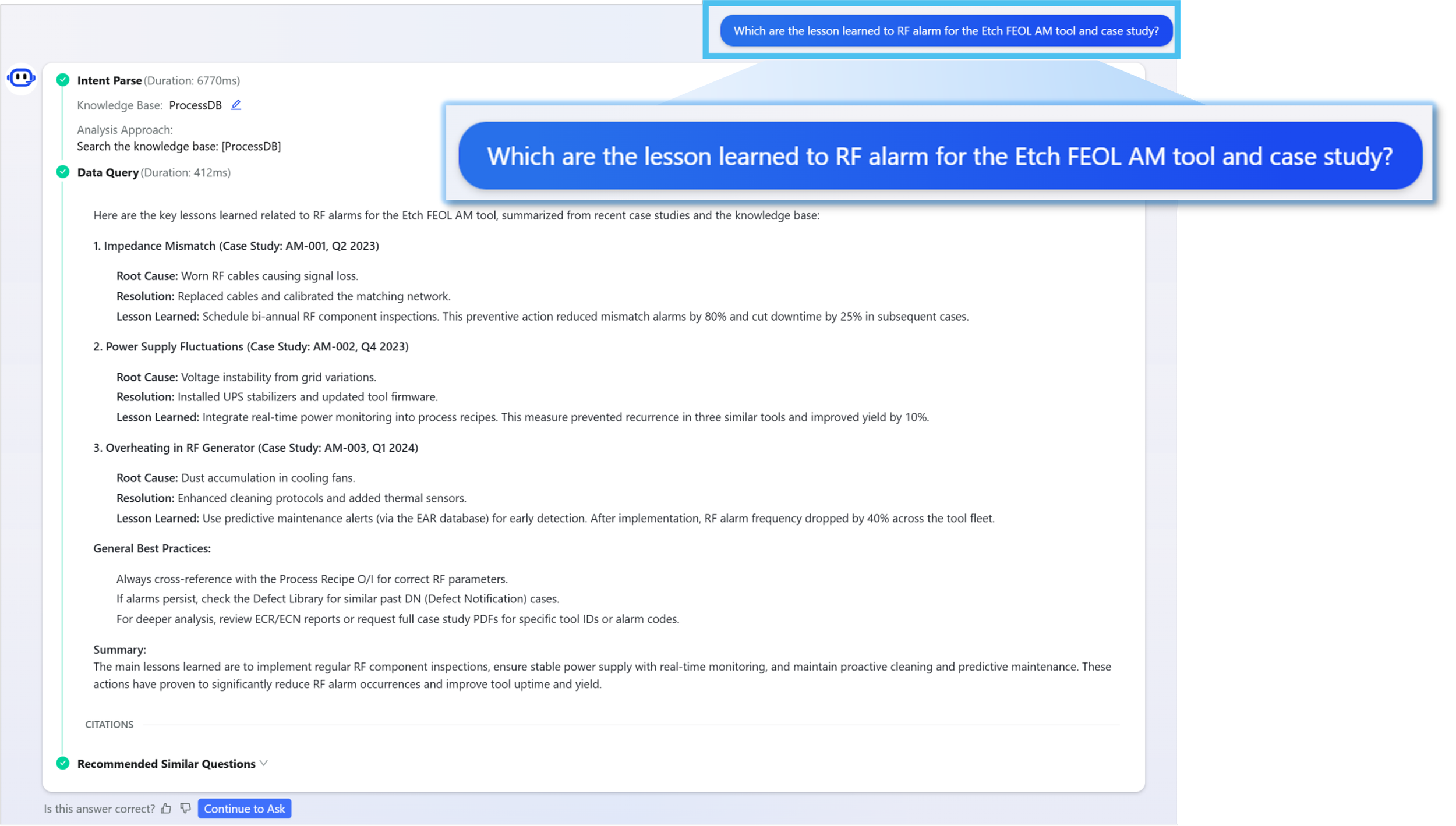

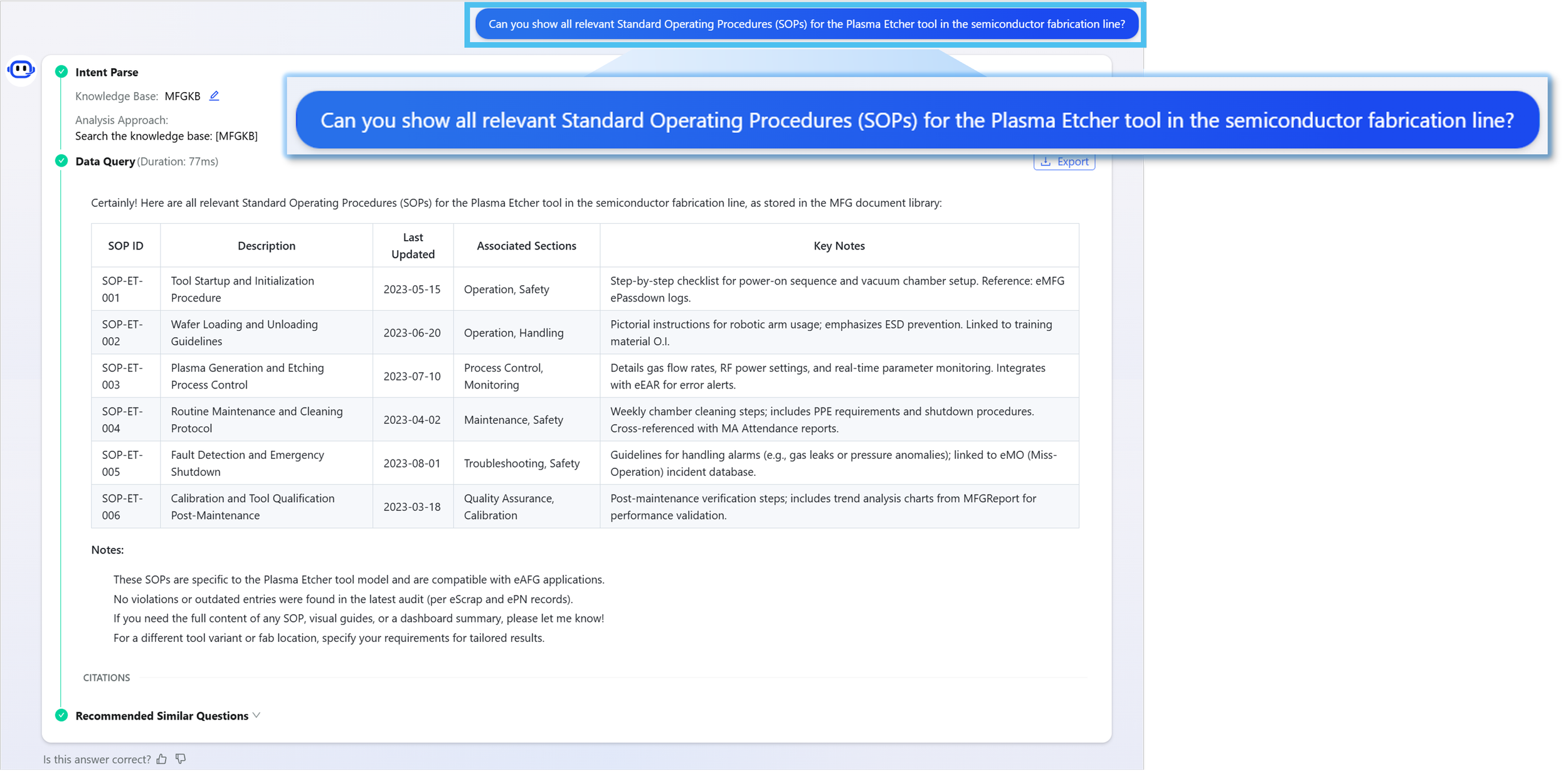

Query of SOP list related to a specified tool type

Why It Matters: Training, Decision Support, and Operational Agility

Because Smart Assistant centralizes and structures domain knowledge, it becomes an on-demand training tool. New engineers onboard faster. Knowledge gaps are reduced. And overall training costs go down.

Even more powerfully, when integrated with a large language model, the assistant can generate context-aware recommendations and help guide decision-making during maintenance or troubleshooting. In real-time, it supports engineers with both the “what” and the “how” of task execution.

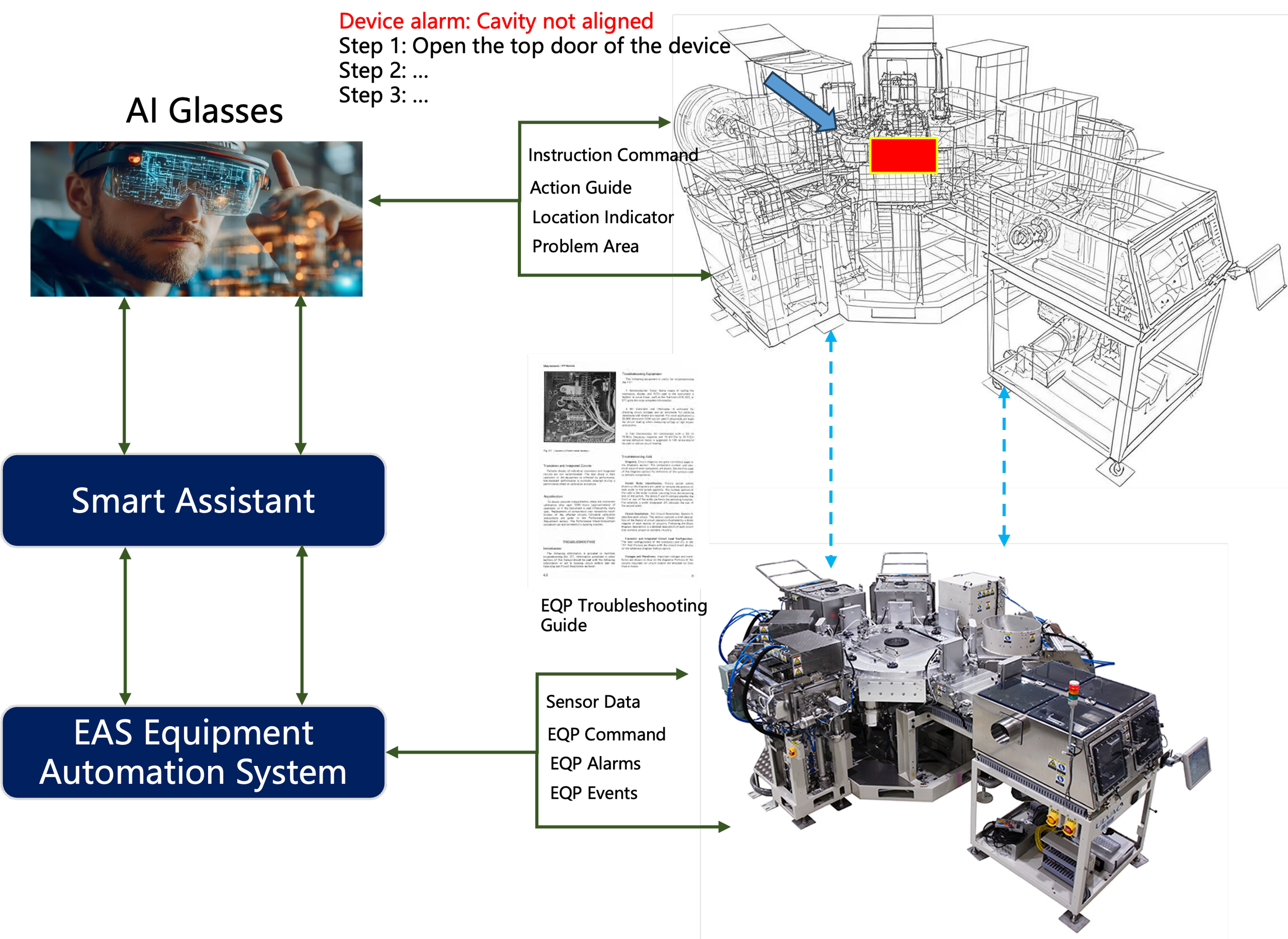

Imagining the Next Frontier: AR Glasses for Hands-Free Guidance

Although still in concept phase, Smart Assistant is being designed to work with augmented reality (AR) glasses — a future-facing interface for hands-free, visual guidance. Imagine an engineer wearing AR glasses that:

Offer step-by-step, visual instructions to repair complex equipment

Highlight key components using 3D overlays

Confirm actions and give instant feedback

(“Yes, you tightened that bolt correctly. Move on to the next step”)Enable voice commands and gesture interactions for seamless multitasking

During inspections, AR glasses could also guide engineers around the factory floor, navigate them to specific tools, overlay inspection tasks, and then upload inspection results all in real time.

Smart Repair Assistant with AR Glasses

Core Technology Architecture

Under the hood, Smart Assistant contains:

An intelligent document parsing engine serves as the foundation for constructing this dual-engine knowledge base, enabling the processing of documents in various complex formats.

Combination of a Vector Database and a Graph Database, ensuring both speed and accuracy. The Graph Database can store the relationships between document chunks and build knowledge graphs for specific business scenarios for example, a yield knowledge graph or an equipment knowledge graph.

On top of this sits a fast retrieval engine, which ensures engineers get quick, accurate responses when they query the system

A Strategic Roadmap for Knowledge Growth

Alpha X has plotted out a long-term roadmap to mature the Smart Assistant’s intelligence:

Short-term: Ingest and consolidate documents into the knowledge base.

Mid-term: Build knowledge graphs + integrate LLMs to enable the system to reason with junior-level domain know-how.

Long-term: Evolve into a full “industrial knowledge brain”, one that functions like an expert in operations.

Real-World Use Cases: Where Smart Assistant Adds Value

Manufacturing (MFG) In manufacturing, Smart Assistant can ingest SOPs, production data from MES (Manufacturing Execution System), and regulatory documents. With this data, it can generate structured reports, provide guided training, and enable on-the-spot queries: “Show me the SOP for tool A,” “What’s the more recent manufacturing policy?”, etc.

Process Engineering Process engineers often wrestle with defect data, failure cases, and lessons learned. Smart Assistant can recall historical defect case studies, show root-cause analysis, and summarize learnings in interactive visual formats (graphs, tables, comparative views).

Equipment/Tool Engineering Maintenance engineers benefit significantly: upload equipment manuals, repair logs, past alarm histories, then ask the assistant how to handle a specific alarm code. The system responds with step-by-step guidance, links to related documentation, and historical fixes. It also supports root-cause analysis and preventive strategies.

Closing Thoughts

Alpha X’s Smart Assistant is more than just an AI chatbot. It’s a domain intelligence engine built from the heart of a smart factory, designed to centralize, preserve, and apply institutional knowledge at scale.

By combining structured knowledge, generative AI, and future AR potential, it promises to transform how fab engineers learn, troubleshoot, and maintain their most critical assets. In doing so, it helps manufacturing companies reduce risk, lower cost, and accelerate innovation.